We have two working lines in the factory. One is manual assembly of parts, another is automatic production line. The automatic production line improves the work efficiency of the workers.

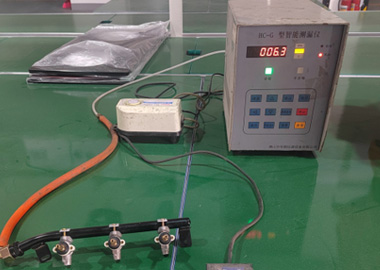

A team of professional and experienced engineers will give instructions to the workers according to the customer’s requirements.

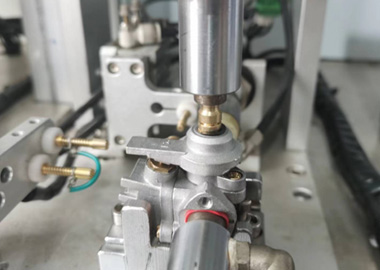

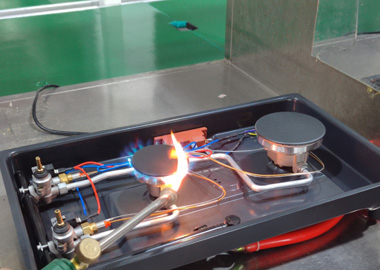

And several workers will be assigned to each process to assemble the parts together, including pan support, brass cap, gas pipe, ignition valve, FFD(Flame Failure Safety Device), burner, and other components.